4 common mistakes people make when hot-plate welding

In our last blog post, we discussed that you only need 2 things to weld plastic, heat and pressure. It really is that simple. However, there are 4 common mistakes that people often make when setting up a hot-plate weld that can prevent adequate heat and pressure from being achieved. Today we’re going to explore these mistakes and how a strong weld can be attained by avoiding them.

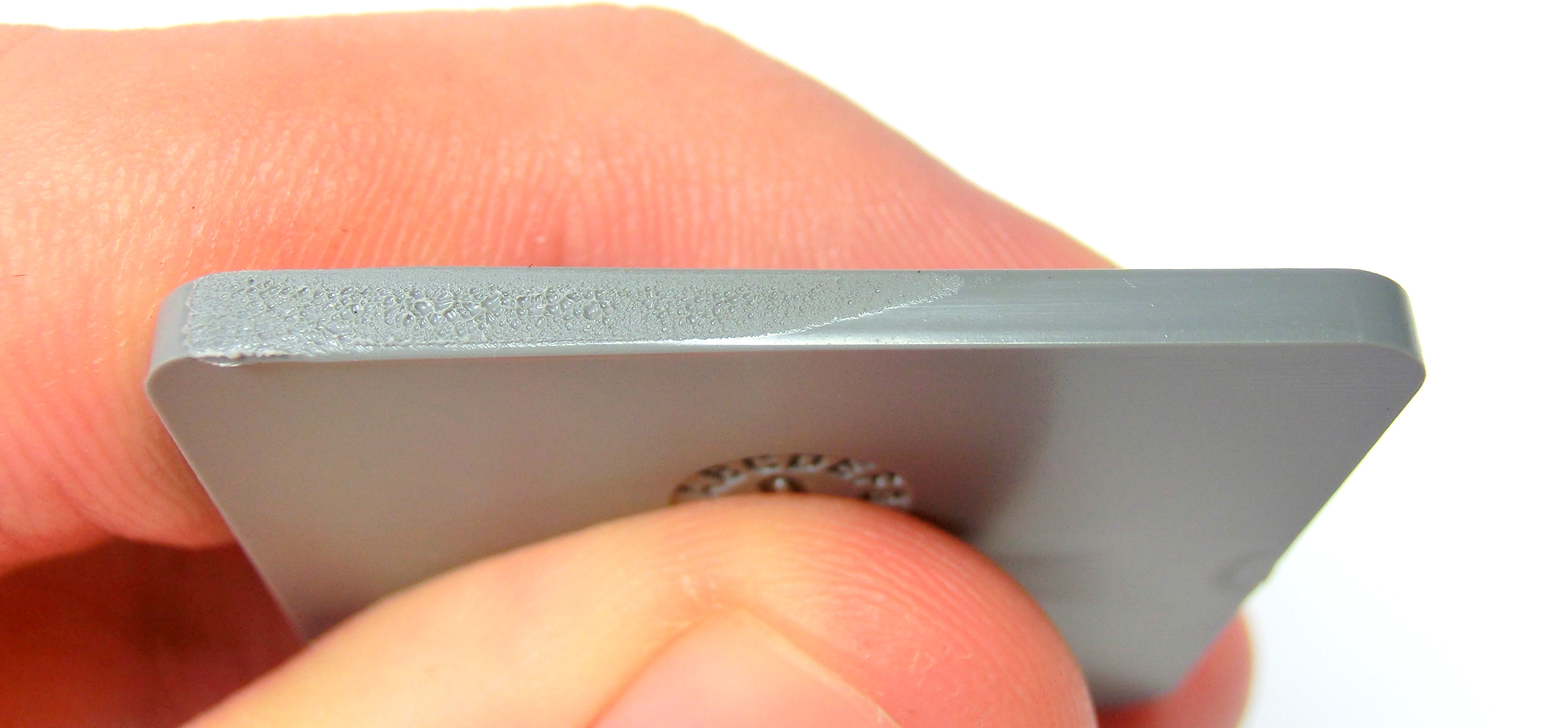

1. Not making contact with the entire melt rib (incorrect melt zero)

To effectively transfer heat into a plastic component, the melt rib must come into full contact with the heated tool. This position, where the heated tool just barely comes into contact with every point on the weld rib surface, is called melt zero. If an incorrect melt zero position is set, portions of the intended weld surface will not absorb enough heat to fully melt and bond. This situation causes what we call a “cold weld.” To avoid this scenario, perform a melt test (melt only, no seal phase) and then inspect the parts to be sure that the entire melt rib surface shows signs of contact with the heated tooling. If portions of the melt rib show no sign of melt, adjust the melt zero position until they do.

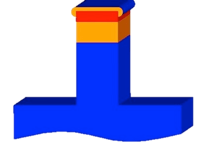

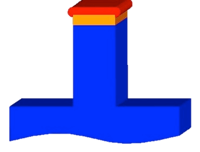

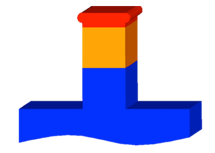

2. Insufficient melt dwell time

In order to create a strong weld, heat needs to penetrate into the plastic weld ribs to allow the material to flow and bond with the softened material from the other half of the assembly. This heat depth is controlled with a programmed melt dwell time. If the melt dwell time is too short, the heat will not soak deeply enough into the weld ribs and will result in a cold, weak weld. Conversely, if the material is allowed to absorb too much heat (via a long melt dwell time), then it will become difficult to apply enough force to achieve a strong weld.

|

|

|

| Ideal Heat Time with Long Open Time | Insufficient Heat Time | Ideal Heat Time |

Legend: Melt Front Softened Material Solid Material

3. Too long of an open time (changeover)

Once the plastic components have been heated, the tooling will retract, and the two components will then be brought together to seal under force. The time from when the components come off the heated tool to when they are brought together is referred to as the “open time” (or, in some cases, “changeover”). It is critical to minimize the open time as much as possible. The longer the open time, the more opportunity the semi-molten weld ribs on the components have to cool off. If the weld ribs cool for too long, they begin to develop a skin on their surface, which inhibits the semi-molten material on the two components from mixing and forming a strong weld. Because of this, it is imperative that the transition between the heat and seal phases is quick and efficient.

4. Insufficient seal force

When the two components are brought together after heating, the force applied to the semi-molten material causes the material from the two halves to mix and weld. However, if insufficient force is applied, the materials won’t adequately mix, which causes a weak weld. On the other hand, if too much force is applied, all of the semi-molten material will be squeezed out of the weld area, leaving only cold material on each side, preventing strong material bonding.