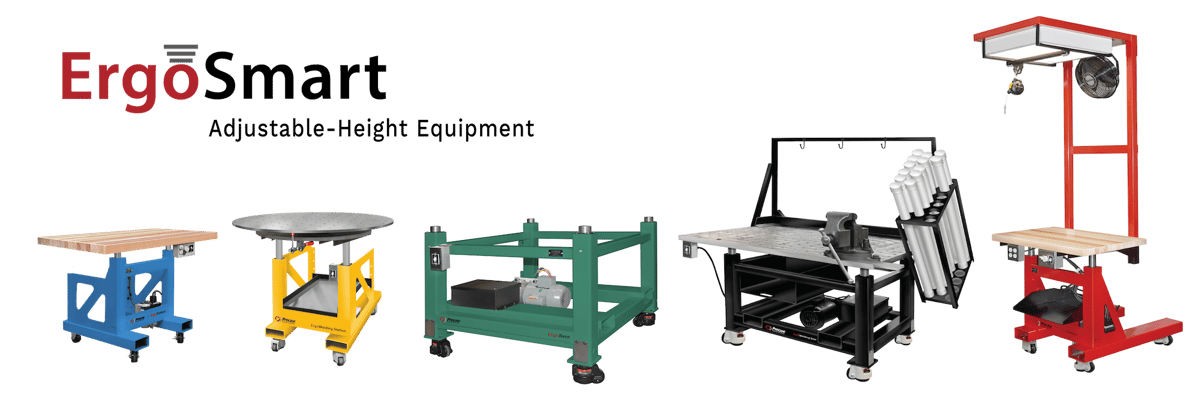

Our ergonomic equipment lets you address multiple manufacturing applications. Both the 2-post and 4-post models feature a full 12” vertical lift cycle and a welded steel frame to provide optimal ergonomic safety in a versatile and affordable package.

Each workstation starts as a welded, heavy duty steel frame — giving it unrivaled structural integrity. Multiple lift posts eliminate table ex and side-to-side frame movement — providing incredible stability A heavy duty electric motor delivers a smooth lift action that provides a comfortable and safe workspace, whether the operator is 5' 6" or 6' 5"

Raise your game with ErgoSmart workstations and lift bases. Prevent back injuries and lower manufacturing costs. Built to order and surprisingly affordable.

![]()

![]()

A welded steel upright accommodates overhead lighting, hand-held tools and other operator convenience items. Standard frame widths are 20”, 24“ and 32”. Standard electric motor has 500 lb lift capacity. A durable powder-coat finish in your choice of RAL colors. Laminate, butcher block and machined tables are availble in widths up to 72”.

ErgoStations provide a safer, more efficient facility while reducing your manufacturing costs. Every unit is built to order in five weeks or less. And best of all, they’ve affordable.

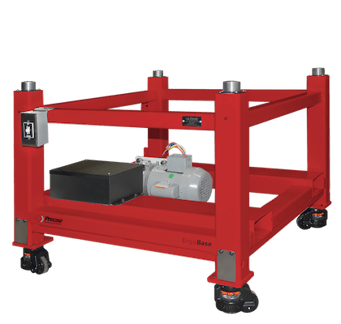

The four-post ErgoBase is a lift base for your heavier applications. Our time-tested design incorporates a heavy-duty chain to deliver a smooth action. Our unique lift post assembly has machined bushings and a proprietary epoxy pour that ensures a perfectly level table and synchronized lift action for years to come. Integrated forklift tubes and dual-purpose leveling casters provide mobility.

We build each unit to order, with frame widths by the inch from 24” to 120”. Pick from hundreds of RAL colors. And we welcome custom designs.

| Assembly |

Material Handling |

Packaging |

Electrical |

Quality Control |

Machining |

Precise Tooling Solutions, Inc. is a specialty manufacturer that builds and repairs injection tooling. We are recognized for our expertise with tight-tolerance optical lighting tools & thermoset molds. We also manage complex CNC machining projects and build ErgoSmart, a line of adjustable-height workstations and lift tables which manufacturers use for assembly and material handling applications. We also have a thorough top of the line equipment list.

© 2019 PRECISE TOOLING SOLUTIONS, INC. ALL RIGHTS RESERVED SITEMAP

PRIVACY POLICY | WEBSITE DISCLAIMER & COPYRIGHT NOTICE | EQUIPMENT LIST