How to develop a robust manufacturing process for a new product

New and innovative products often bring unique manufacturing challenges. There are a lot of questions to answer…

- How are we going to make that in production?

- How do we scale?

- What type of custom automation will we need to manufacture a product that has never been made before?

- How do we know that the equipment will work?

- How can we make sure it operates smoothly?

You don’t have to tackle these on your own. Extol can help you discover and develop a robust manufacturing process. Partner with us early to help refine your budget and win more business with your customers.

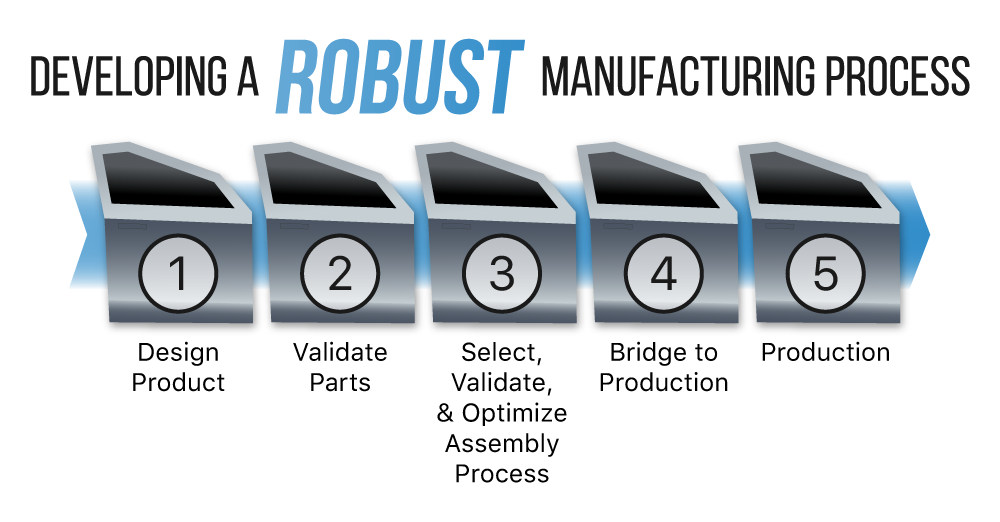

Here is how Extol helps you from the earliest stages of product development to the final details of high-volume production:

1 - Design product

You are the expert in how your product will work. And we are experts in how to assemble it. Together, we’ll help you design your product for assembly. Send us your early concepts and we’ll help you incorporate features to make assembly easy.

2 - Validate parts

Once you have an initial part design, we’ll help you prototype it. You can have strong, functional, 3D printed parts in a few days from Extol’s Digital Development Center. These parts can be welded, glued, snapped, or assembled like production parts. Holding your parts in hand illuminates any design issues so you can quickly optimize the design.

3 - Select, validate, and optimize assembly process

You can also use prototype parts to determine the best way to put them together. Our goal is to come up with a process that can be automated. We often start by assembling components by hand to test out various manufacturing theories. Then we pick the methods that work best and fabricate prototype tooling to validate. As we go, we refine the process and tackle any challenges we discover. Our goal is a capable manufacturing process that operates smoothly. Once you feel confident with the process, we’ll help you scale it for production.

4 - Bridge to production

If initial product volumes are low, capital investment can be difficult to justify. You may want to wait to buy equipment. Or sometimes new equipment is purchased, but not ready in time to meet product delivery deadlines. In either scenario, we can build parts for you to meet your needs.

5 - Production

When the time comes to invest in equipment, we make things easy. Extol will design, build, and optimize your manufacturing equipment to meet your unique needs. We’ll then support the equipment to make sure you stay up and running smoothly.

Partner with Extol

So, are you trying to solve your manufacturing challenge on your own? It’s time to make life easier and partner with Extol. Wherever you are on your journey, we can help you save time, money, and headaches with a capable manufacturing process.

Fill out the contact form below to get started today! 👇