The 4 Reliable Methods for Controlling & Predicting Laser Weld Quality

Laser welding is a widely used method in plastic welding, particularly when precise and clean parts are required. But how can we be sure that the weld is of good quality? We utilize four reliable methods in our manufacturing process to ensure that we have achieved a high-quality laser weld. Through these methods, we can control and predict the quality of the weld, ultimately leading to better outcomes.

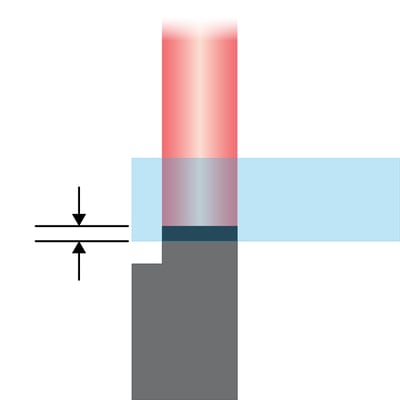

Depth

One of the easiest methods to measure the quality of the weld is to determine how far the parts have collapsed into one another. Controlling the weld depth allows consistent energy to be put into the part and ensures the parts are melting into one another. By running simple tests during process setup, we can determine the optimal power, laser speed, and weld depth for the highest performance based on strength and aesthetics.

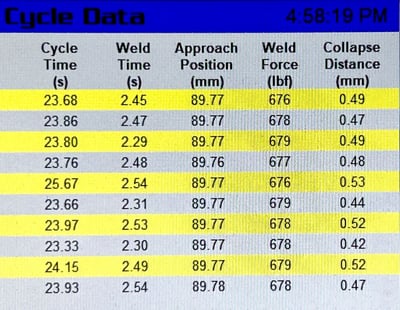

Depth and Time

We can predict failures before they occur by welding in depth mode and setting alarm limits on weld time. After running proper sample sizes, the time it takes to complete the weld becomes clear. You'll usually find a window of weld time that consistently produces good parts. We then use both variables to ensure the mold or weld process is not shifting.

Vision

Sometimes, the parts can be optically inspected to showcase a good weld. For example, we use optical vision inspection systems that use a combination of specialized lighting, filters, and sophisticated cameras to analyze the weld area. This ensures that the weld is high quality and vastly improves the speed and reliability of the quality assurance process, making it an indispensable tool in plastic welding.

Leak Detection

Using in-line leak detection in a manufacturing cell is another excellent way to increase confidence in the laser weld quality. By measuring the leak rate of the welded assembly, you can verify that the weld is good. This can be done in the welding machine or a separate station after welding.

How to get help

Finding the right technology can be tricky, which is why we have a whole department at Extol whose job is to help customers determine the best technology for putting plastic together. With any plastic welding application, having a knowledgeable partner to guide you to the best welding technology and manufacturing solution is best.

Learn more about plastic welding or get started by sending us a message below.