Hot plate welding brackets, ports, and other small components

Trying to hot plate weld small brackets, or ports onto a large complex part can be tough and expensive in a standard machine. These types of applications often need a modular, configurable solution to fit around the parts. Often, the main piece has several small components, each needing a welding operation. For example, many automotive underhood ducts are long and meandering and have a couple of ports and brackets.

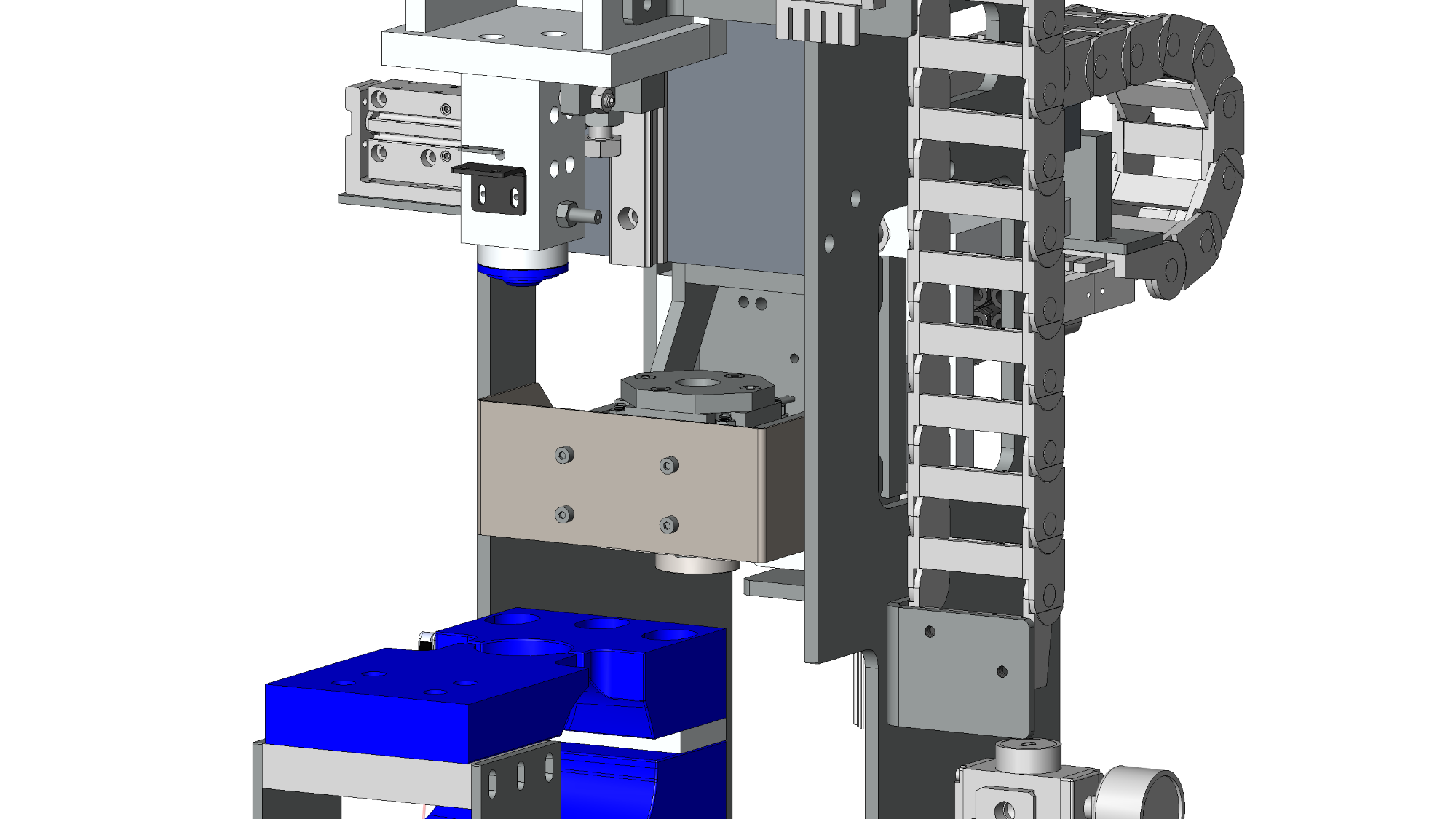

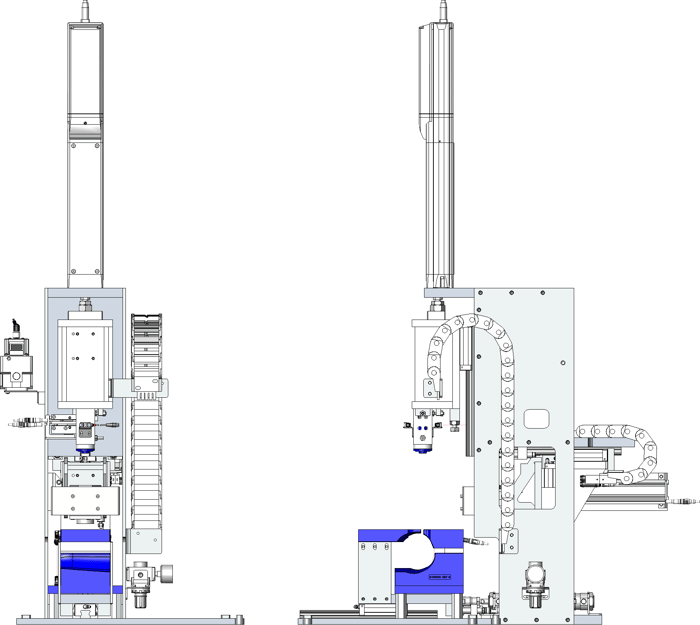

In these applications, Extol's modular hot plate welders come in handy. They're ideal for small, flat welds on larger parts. We customize these highly configurable welders to meet the needs of your application. Generally, though, they operate as follows: Lower tooling holds the larger part fixed. The upper part moves up and down via servo or electro-pneumatic control. And the hot plate slides between the upper and lower via air cylinder.

During welding, the upper part sandwiches the hot plate and pushes it into the lower. Once melting is complete, the upper tooling backs off and the hot plate retracts out of the way. Lastly, the upper part presses into the lower, welding the two together.

There are several benefits to using a modular hot plate welding system:

Modular hot plate welders save floorspace. In most cases, the welder is less than a foot wide and only a couple of feet deep. This is tiny compared to the size of most standard hot plate welders. Floorspace is valuable. So modular hot plate welders offer significant value here.

Modular hot plate welders are configurable. There are countless ways in which we customize these machines. They can have a horizontal or vertical heat plate. Servos or pneumatics can control the press motion. We’ve even configured modular welders to join two parts to one larger part at the same time. You get the idea. We configure the welding solution around your needs.

Modular hot plate welders are cost-effective. These welders are only built with what they need to perform in manufacturing. There are no extras. They often use a small hot plate, so they don't take much energy to keep hot. All this means they are affordable to build and operate.

Ultimately, modular hot plate welders are small, configurable, and cost-effective. They are the ideal hot plate welding machine for small, flat welds on both large and small parts. Contact us today to see how we can configure a solution for your project.