Start monitoring melt force to improve your hot-plate welding process

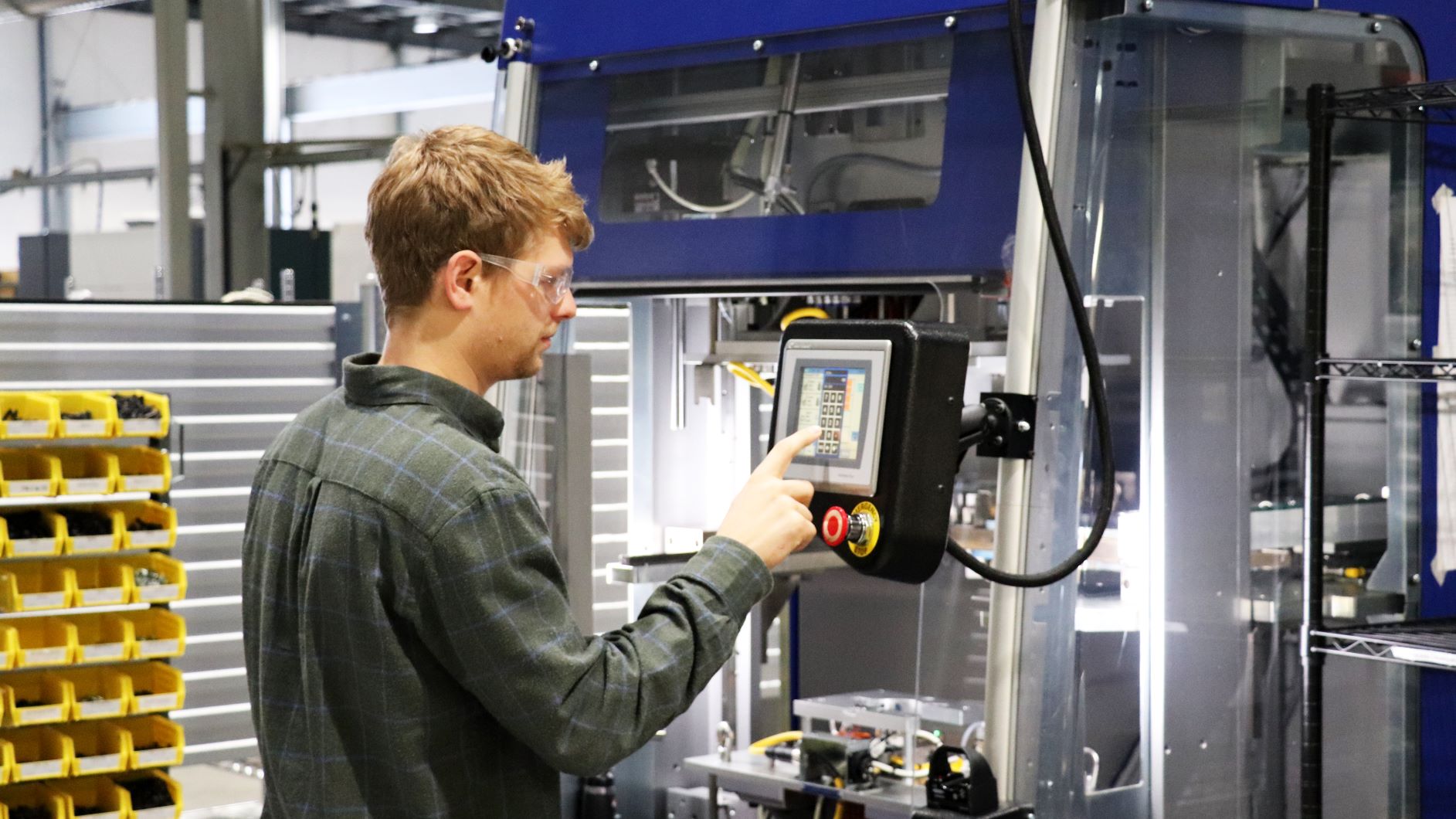

If you do any hot-plate welding, you should start monitoring melt force to improve your weld consistency and quality. Extol’s Rapid Conductor hot-plate welder is equipped standard with three servo-driven platens: the upper and lower press platens, and the heated platen. Servo control eliminates the need for hard stops and ensures that all the pressure applied by the welder goes directly into the components being welded. It also allows the machine to control and monitor the forces throughout the process. Being able to measure the melt and seal forces means you can quickly detect and correct issues.

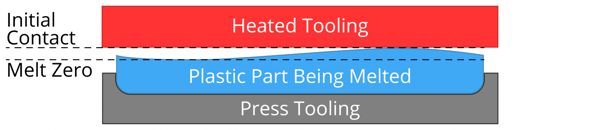

Recently, a customer contacted our service department in search of a solution to their high scrap rate. They were losing 20-30% of their production due to leak failures. Extol’s service team was able to identify the issue: a maintenance technician had adjusted the melt zero position, which is a parameter that is supposed to set where the parts first make full contact with the heated tooling. If the melt zero position is set too low, the parts won’t make full contact and there could be un-melted areas on the weld rib. This also causes a reduction in the melt force being applied, which could have been detected if the customer had been monitoring the melt force with pass/fail limits.

Utilization of the available process monitoring features would have avoided the loss of time and material scrapped. This feature is standard in each machine and monitoring the melt force from the machine SPC data would have flagged the concern before it became a problem. The Rapid Conductor is capable of monitoring and recording the melt forces used to reach the full melt depth in every cycle.

Here are some other issues that could be detected and avoided by monitoring melt force.

- Already melted component. If an operator accidentally welds components that had already been partially melted, the welder would detect a low melt force. A previously melted part could be from the setup process, or parts that were used to troubleshoot an issue. By setting a lower limit to the melt force, the Rapid Conductor will catch these parts, preventing potential bad parts from getting to your customer.

- Improperly loaded part. Occasionally a part design may allow it to be loaded incorrectly, potentially causing the weld rib to be high in some areas and lower in others. This would cause higher than normal melt forces, and an upper melt force limit would flag the issue.

- Excessive molding flash. Additionally, a part that has excessive molding flash could cause higher melt forces, due to the extra material. As before, an upper melt force limit would stop these parts from getting out the door.

These are just a few of the issues that can be identified by setting upper and lower limits to melt force. To set these limits, you should first weld a batch of known good parts in a production setting. Next, review the SPC data recorded by the machine. Determine the appropriate upper and lower limits for both the upper platen and the lower platen (they operate independently of each other). Set the limits, then test them to see if they detect a bad part.

As always, if you need assistance with your hot-plate welding process, you can contact us for help.