Plastic Joining: Make or Break Factors

"What technology should I use to join my application?" is one of the most common questions we get from customers looking to ensure the best performance and durability for their project. Unfortunately, there's no one-size-fits-all answer to that question. Several factors go into whether or not an application is compatible with different plastic welding technologies, and understanding them is key to making an informed decision.

Here's a list of application details that should be taken into consideration when looking for joining guidance:

Hermetic Seal: Does the assembly need to be air or water-tight at a set operating pressure?

High Burst Strength: Will the assembly need to withstand high internal pressure before failure?

High Tensile Strength: Will the assembly need to withstand high pull forces?

Complex Geometries: Is the joint complicated with contours and unique shapes?

No Particulate: Must the assembly be clean, with no dust particles from the joining process?

Internal Welds: Are there additional welding surfaces inside the perimeter of the assembly?

Tall, Unsupported Walls: Are the outer walls over an inch high? Do they include features that allow tooling to support directly behind the weld surface?

Thin Walls: Are the assembly walls less than 1.5 mm thick? Thin walls may warp, bend, or buckle under welding forces.

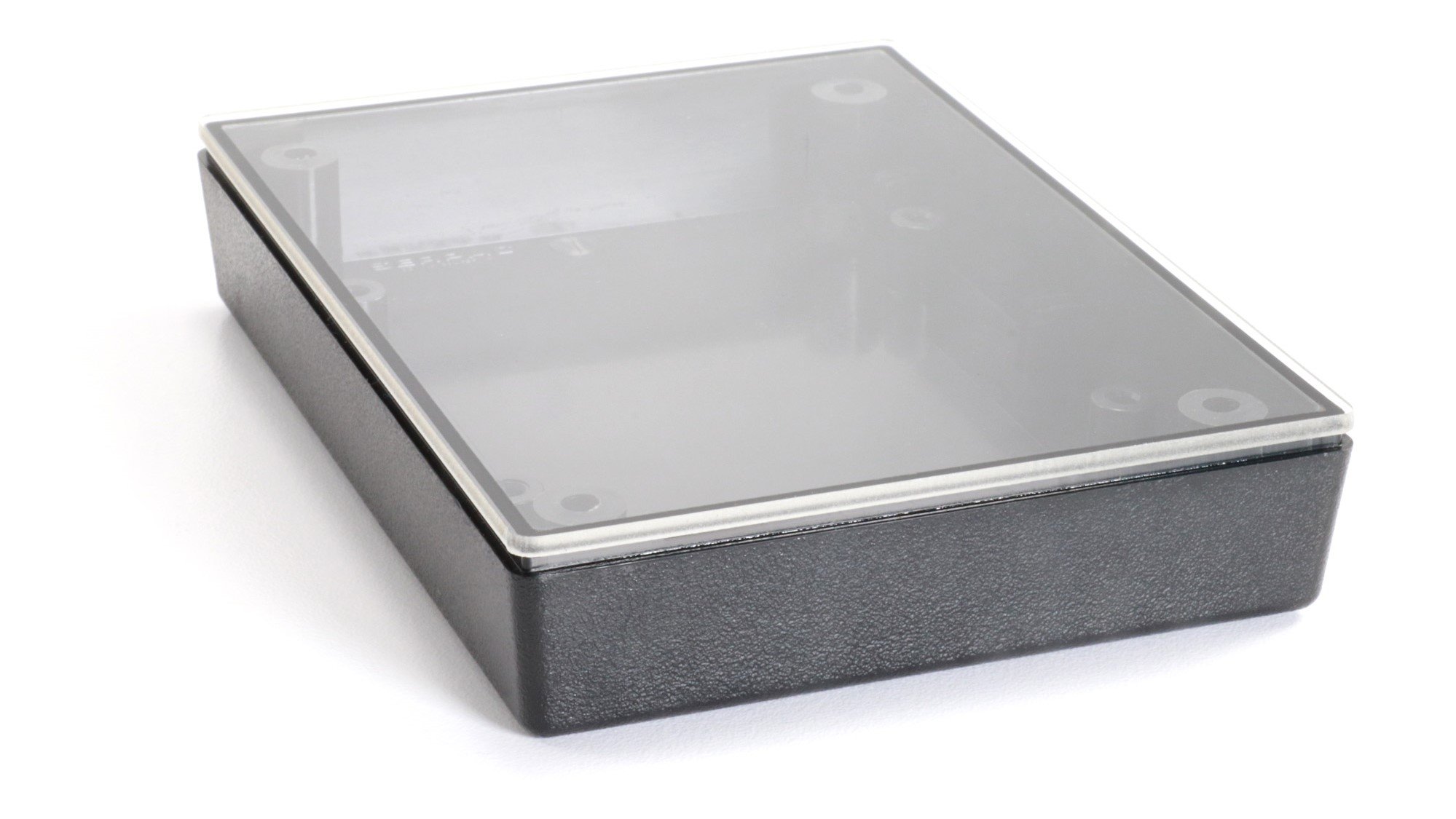

Internal Components: Are there additional components within the assembly that are not welded or staked? For example, gears, PCBs, gaskets, and more.

Incompatible Materials: Are the components being welded chemically compatible with each other? If not, they can't form a molecular bond.

Sticky Materials: Are the materials sticky and troublesome for contact welding processes despite non-stick coatings? For example, PA, PBT, PC, and HDPE.

How do I see what technology is best for my material needs?

We put together a chart comparing how our plastic welding technologies work when up against the factors above. We encourage you to download it and use it as guidance as you consider which technology would be best for your application. While there are many other factors that go into the decision of which technology is used, this can serve as a starting point. If you're ready to talk through your application or have questions, we are here! Send us a note using the form below and we'll get you in contact with one of our plastic welding experts.