A staking process for lighting and electronics

How many times have you stared at a plastic staking machine and wondered how long of a cool time is necessary to prevent the material from sticking to the forming tool when it retracts? Will the settings need to be adjusted after the machine has been running for a while? You need to make good parts, but you also want to optimize the machine cycle time. And naturally, the staking modules need to be small enough to fit your application. Automotive lighting and electronics manufacturers especially need a staking process that fits in tight spaces, keeps up with production, and is simple to set up and operate. Enter nanoSTAKE®, a patented, revolutionary staking technology that fits the bill.

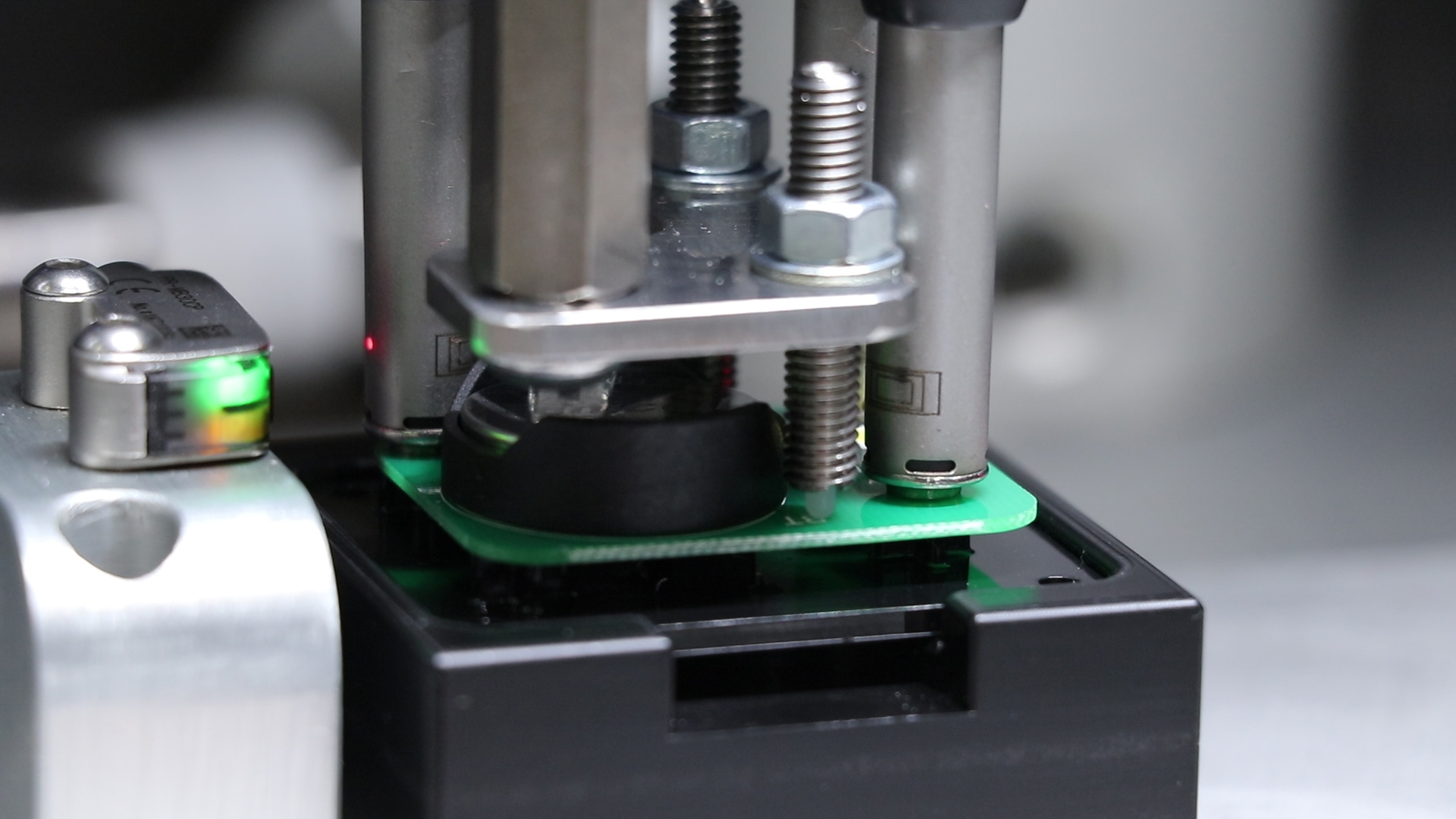

First, nanoSTAKE modules are small… really small, like the size of a pencil small. So, they can easily fit next to each other to stake bosses that are close together and they can fit into small, difficult-to-reach areas of a plastic assembly.

Next, unlike other staking technologies, nanoSTAKE is precisely controlled by temperature, not time. That means you don’t set a heat and cool time and no longer have to guess how long they should be. Instead, nanoSTAKE uses a low-current, high-performance heating system called Smart Respond™ which includes an embedded temperature sensor that provides true closed-loop control.

Here’s how it works. The nanoSTAKE punch is rapidly heated to a programmed melt temperature in seconds. While maintaining a precise temperature, the punch forms the boss into a stake. A position sensor verifies the stake is fully formed and triggers the cooling phase. Next, the module rapidly cools to a programmed release temperature, which ensures the material resolidifies and doesn’t stick to the punch. Finally, the cooled module retracts and is safe to touch. NanoSTAKE modules even include an LED indicator to show the state of the module throughout the process. That way, you know exactly what they’re doing all the time.

Furthermore, because of its rapid heating and cooling capabilities, the process reaches steady-state every cycle. This means that a nanoSTAKE machine doesn’t have to “warm up”. It makes good parts starting with the first cycle and will run all day without needing adjustment.

Finally, there is a staking technology that is small, fast, and easy to use. With nanoSTAKE, you get a process that produces high-quality, fully-formed stakes and is simple and safe to set up and operate.

Ready to get nanoSTAKE on your project? Use the contact form below to get in touch!