Blog

4 common mistakes people make when hot-plate welding

September 07, 2023

In our last blog post, we discussed that you only need 2 things to weld plastic, heat and pressure....

How to reduce weight, space, and cost of a headliner assembly

August 31, 2023

What if I told you that you can reduce the weight and space of a headliner assembly while attaching...

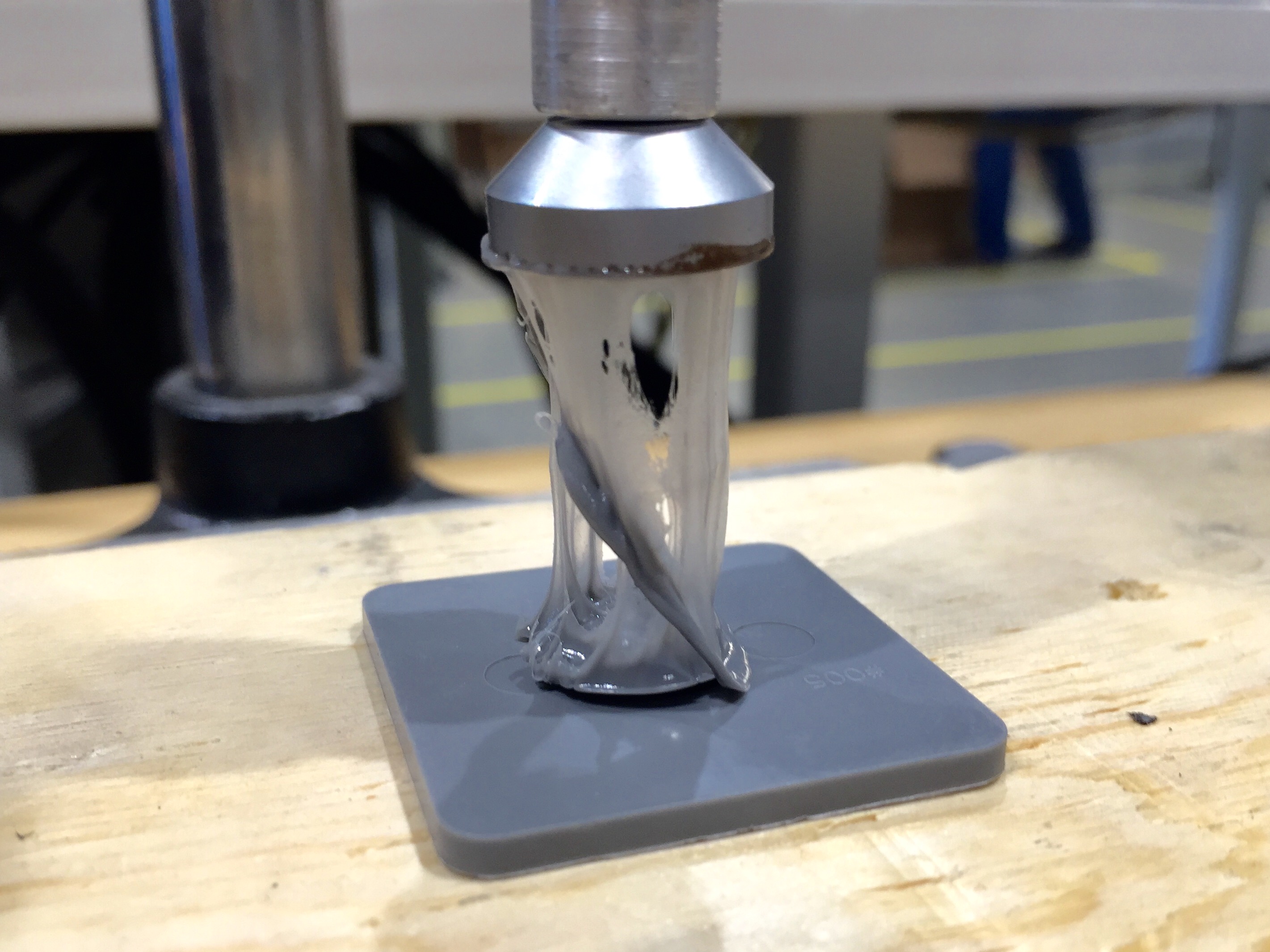

Why you see flash when staking plastic and how to optimize it

August 24, 2023

Understanding Flash in Plastic Staking The moment is here, the process is set, the machine has...

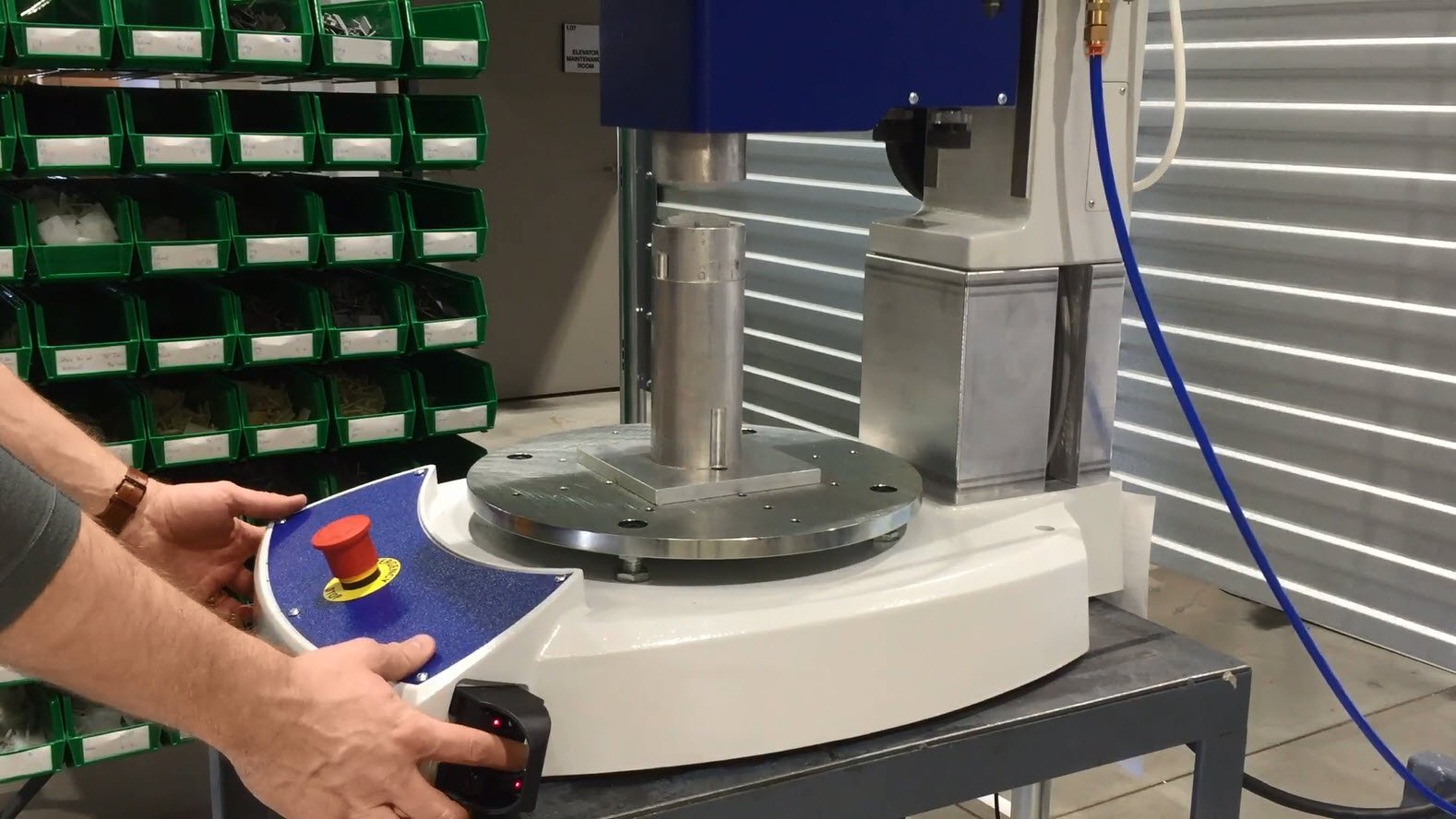

Discovering nanoSTAKE for the first time

August 17, 2023

A few years ago, while spending some time in our Innovation Group, one of our company’s founders...

When to use hot-plate welding

August 04, 2023

When considering the common plastics joining methods for assembling a new product, hot-plate...

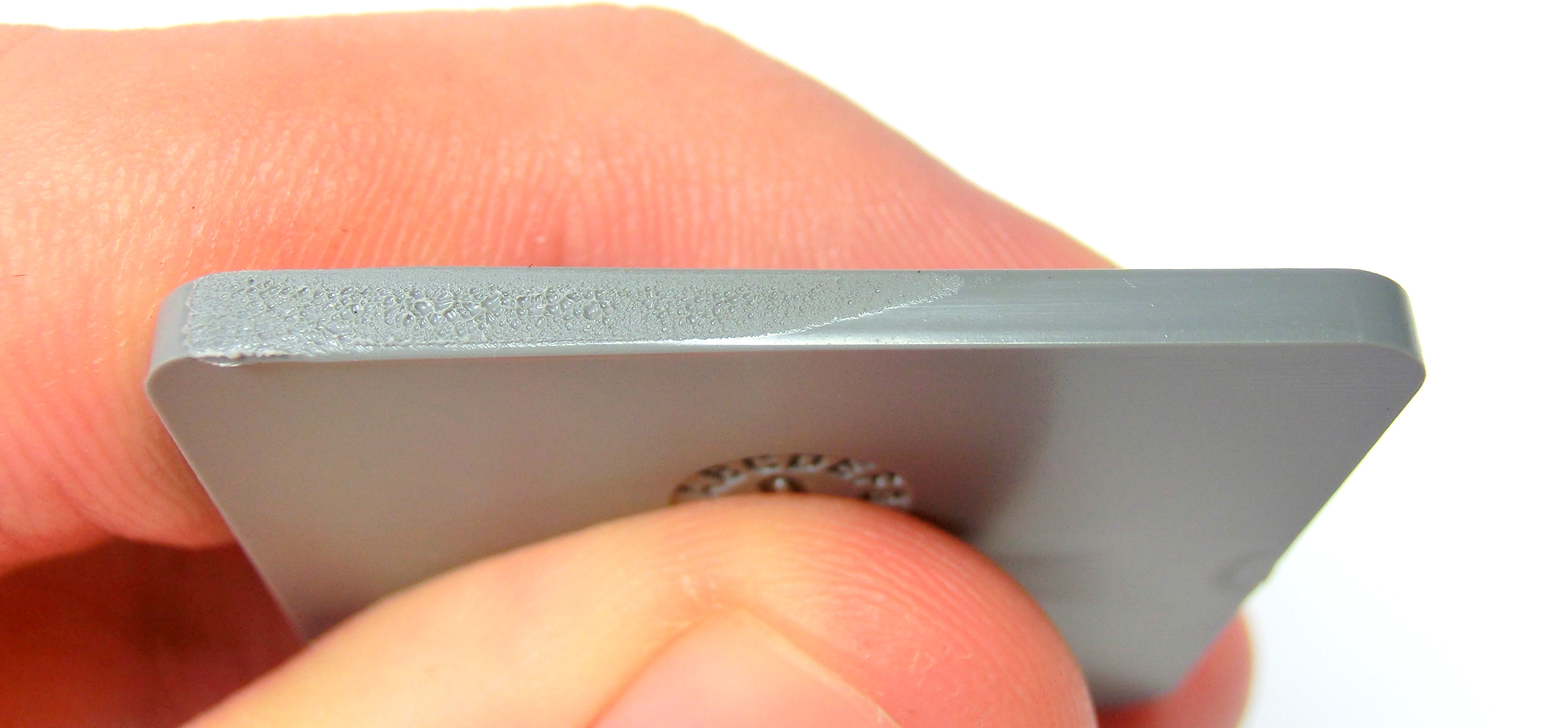

Why is my plastic sticking during the staking process?

July 28, 2023

This question has been posed to me by many customers. I hear statements like, “The machine works...

4 spin welding tips to think about

July 20, 2023

Spin welding is a really good method for joining thermoplastics. It’s easy to understand, the...

Ultrasonic or Hot-Plate Welding? The Battle for Superiority in Medical Device Assembly

July 11, 2023

Welcome to our exploration into plastic welding for life science applications. As we embark on this...

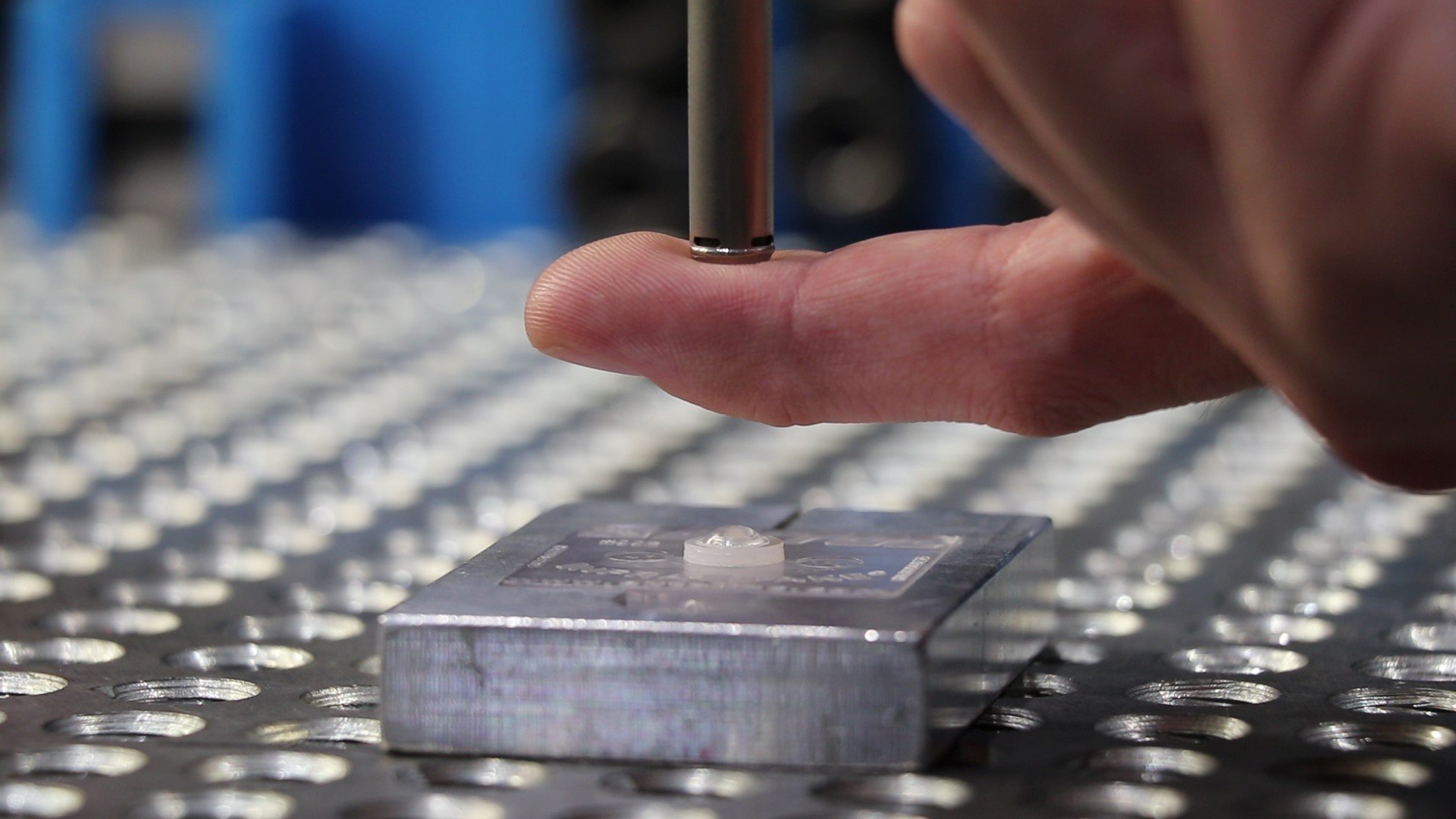

How to design for plastic staking

June 22, 2023

Introduction Understanding the latest technologies and best practices is crucial for designers and...

The Guide to Switch from Adhesive Bonding to Plastic Welding

May 24, 2023

Introduction In manufacturing and product assembly, choosing the proper joining method is critical...

Archive

- November 2025 (2)

- June 2025 (3)

- June 2024 (1)

- February 2024 (1)

- January 2024 (1)

- September 2023 (3)

- August 2023 (4)

- July 2023 (3)

- June 2023 (1)

- May 2023 (2)

- April 2023 (1)

- March 2023 (2)

- November 2022 (2)

- February 2022 (1)

- January 2022 (1)

- October 2021 (1)

- June 2021 (1)

- March 2021 (1)

- December 2020 (2)

- November 2020 (1)

- October 2020 (1)

- August 2020 (1)

- May 2020 (1)

- April 2020 (1)

- February 2020 (1)

- September 2019 (2)

- August 2019 (1)

- June 2019 (1)

- March 2019 (1)

- January 2019 (1)

- November 2018 (1)

- October 2018 (1)

- September 2018 (1)

- April 2018 (1)

- December 2017 (1)

- September 2017 (1)

- July 2017 (3)

- June 2017 (1)

- April 2017 (1)

- March 2017 (1)

- February 2017 (1)

- December 2016 (1)

- May 2016 (1)

- March 2015 (1)

- November 2014 (1)